Showroom

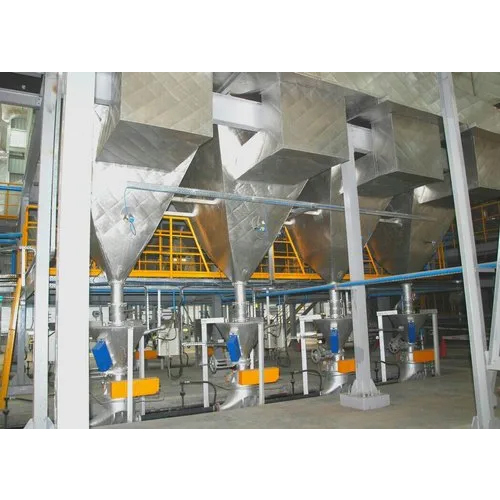

This system is completely leakage proof and ash even in small quantity does not spill out. Each of the equipment adjusted to this system is crafted from best quality raw material to avoid any type of contamination. It requires less energy to work and provides handling of ash for a very long time. Furthermore, this system is helpful in handling huge amount of ash at various places like construction sites, cleaning machines, etc.

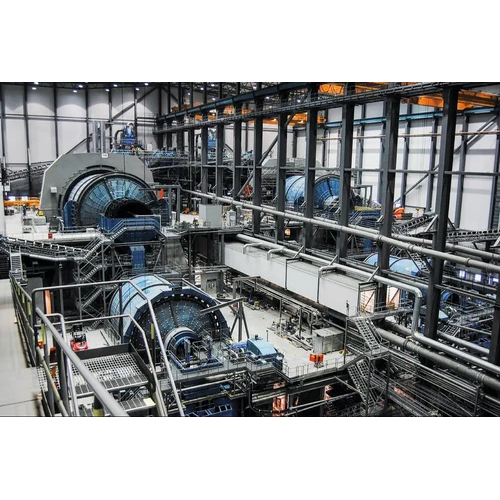

This Biomass Handling System runs on optimum energy and provides the handling of biomass gas for a long time. Every equipment that is adjusted to this system is processed under advanced machines by making the use of robust techniques. It provides the transferring and storing of biomass gas in large quantity without incurring any leakage or contamination.

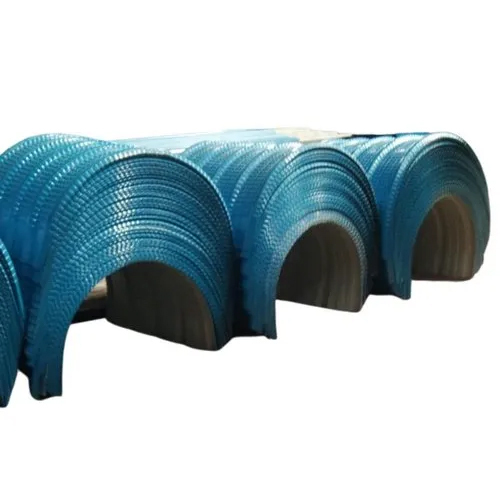

Being crafted out of best quality raw material, the complete range of this Belt Conveyor Accessories is light in weight and highly durable. These accessories provide efficiency to the belt conveyors for their flawless movement in a rapid manner. These are compact in size and do not require any type of oiling and greasing.

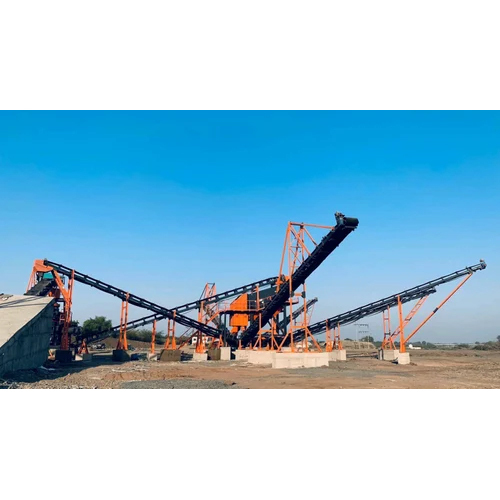

Our Coal Handling System consists of a tripper conveyor system that is used for bunker feeding. This complete system has special features like dust extraction, suppression, etc, to avoid any type of damage. It can effectively handle the coal at various construction sites and structures. The entire range of equipment attached to this system are robustly made to give it a corrosion free surface and a longer servicing life.

Having a wide range of application at various places, this Vibrating Screen can effectively separate the feeds with solid particles from wet or dry faces. It can attain a high speed vibration for proper separation of the particles. It has extra features like corrosion free surface, light in weight and leakage proof surface. Furthermore, it can work flawlessly for a considerably long time.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese