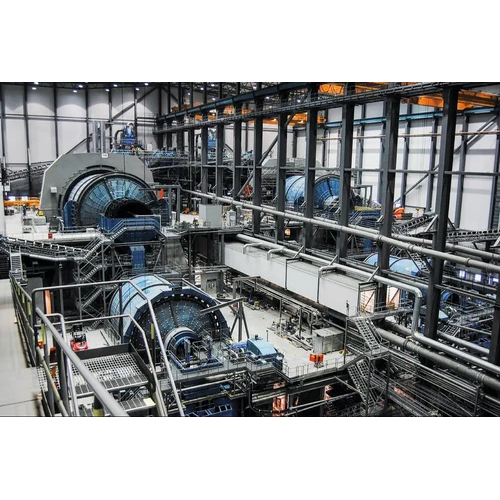

Fuel Handling Plant

Price 15000000 INR/ Piece

MOQ : 1 Piece

Fuel Handling Plant Specification

- Efficiency

- 95 %

- Automation Grade

- Fully Automatic

- Usage & Applications

- Industrial

- Power Source

- Electricity

- Product Type

- Fuel Handling Plant

- Material

- Mild Steel

- Voltage

- 220-440 Volt (v)

- Warranty

- 1 Year

Fuel Handling Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1-2 Week

About Fuel Handling Plant

Rollcons Fuel Handling Plant is a turnkey system designed for smooth, efficient movement of coal, biomass, or RDF in power and process plants. Engineered for heavy-duty use and minimal downtime. With 700+ global installations, we deliver worldwide.

Key Features:

- Handles coal, bagasse, wood chips, RDF

- Includes crushers, conveyors, feeders, storage

- Energy-efficient and customizable

- Built for rough environments

Superior Efficiency and Automation

This fuel handling plant is engineered to optimize industrial fuel management with a remarkable 95% efficiency rate. Designed for fully automatic operation, it reduces manual intervention and ensures consistent, reliable performance. The robust mild steel construction enhances both durability and safety, making it a dependable asset for heavy-duty industrial applications. The automated processes not only improve throughput but also minimize operational errors, providing greater peace of mind during fuel handling tasks.

Versatile Power Compatibility

With a voltage range of 220-440V, this plant is compatible with a variety of industrial electrical setups. The integration of a reliable electrical power source means stable operations, reduced downtime, and lower maintenance needs. This versatility ensures the plant fits seamlessly into various industrial sites and adapts to unique infrastructural requirements present across different sectors in India and abroad. The wide voltage capacity makes it a practical choice for diverse applications.

FAQ's of Fuel Handling Plant:

Q: How does the Fuel Handling Plant work in an industrial environment?

A: The Fuel Handling Plant automates the collection, transfer, and distribution of fuel within industrial settings. Utilizing electrical power, it operates fully automatically, minimizing manual labor and enhancing operational safety and consistency.Q: What materials are used in the construction of the plant?

A: The plant is constructed from high-quality mild steel, chosen for its durability, resistance to corrosion, and long service life, making it suitable for demanding industrial use.Q: When should maintenance be performed on the Fuel Handling Plant?

A: While the plant is robust and requires minimal maintenance due to its automated systems, periodic inspections as recommended in the user manual are advised to ensure optimal performance and extend the equipment's lifespan.Q: Where can this plant be installed?

A: The Fuel Handling Plant is designed for industrial installations, compatible with facilities across various sectors in India and for export markets. Its voltage range and construction allow for flexible site adaptation.Q: What is the process for installing and commissioning the plant?

A: Our team manages the installation process, which includes site assessment, equipment setup, and system integration. After installation, we conduct commissioning tests to ensure safe, efficient operation in compliance with industrial standards.Q: How is the plant powered, and what voltage range does it support?

A: The plant is powered by electricity and supports a voltage range of 220-440V, making it adaptable to most industrial power supply standards.Q: What are the key benefits of using this fuel handling plant?

A: With high efficiency, automation, robust build, and comprehensive warranty, the plant delivers reliable, safe, and cost-effective fuel handling, reducing downtime and operational risks in industrial settings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Power Plant Category

Waste Treatment Plants

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Power Source : Electricity

Material : Mild Steel

Voltage : 220440 Volt (v)

Product Type : Waste Treatment Plants

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese