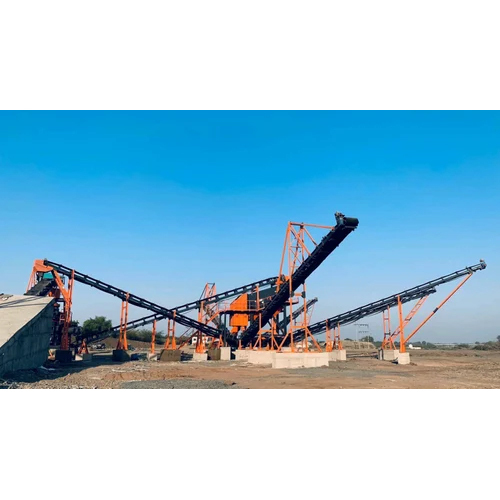

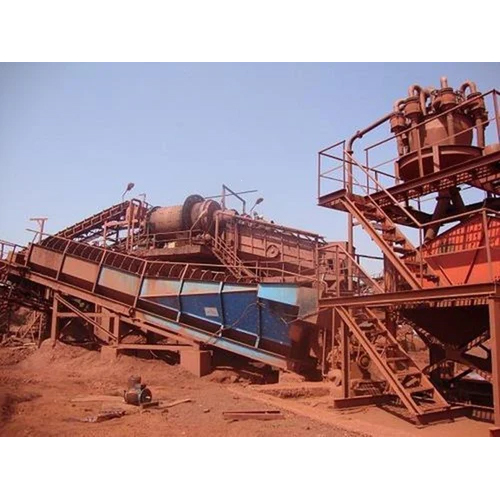

Bauxite Processing Plant

Price 4000000 INR/ Piece

MOQ : 1 Piece

Bauxite Processing Plant Specification

- Installation

- On-site Installation Available

- Type

- Processing Plant

- Product Form

- Complete Turnkey Solution

- Condition

- New

- Capacity

- Customizable as per requirement

- Voltage

- 220-440 V

- Corrosion Resistance

- Yes

- Power Consumption

- Low Power Consumption

- After Sales Service

- Available

- Application

- Industrial

- Power Source

- Electric

- Usage

- Refinery, Mining, Chemical Processing

- Automatic Grade

- Automatic

- Driven Type

- Electric

- Operation Mode

- Semi-Automatic/Automatic

- Surface Treatment

- Paint Coated

- Material

- Bauxite

Bauxite Processing Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 1-2 Week

About Bauxite Processing Plant

Bauxite Processing Plant Rollcons Bauxite Processing Plant is built to streamline crushing, sizing, and beneficiation of bauxite oremaking it suitable for use in alumina production and other industrial applications. Our systems offer high recovery, minimal handling loss, and low operational costs. With 700+ successful projects globally, Rollcon delivers tailored, efficient solutions. We deliver worldwide.

Key Features:

- Specialized design for sticky and abrasive bauxite

- Efficient classification and dewatering setup

- Compact plant layout with minimal civil work

- Fully customizable based on ore quality and capacity

Customizable Turnkey Solutions

Our bauxite processing plants are designed to adapt to varying capacity requirements, offering complete turnkey solutions for mining, refinery, and chemical sectors. Each plant can be customized for optimal integration into your existing operations, ensuring heightened efficiency and seamless compatibility.

Efficient Power and Advanced Automation

Engineered for low power consumption, these plants are available in semi-automatic or fully automatic modes. The electric-driven design, operating between 220-440 V, ensures stable performance and reduced operational costs, while the modern control systems facilitate easy and precise management.

Comprehensive Support and Durability

Benefit from on-site installation and reliable after-sales support, allowing for smooth commissioning and sustained productivity. The corrosion-resistant, paint-coated construction guarantees longevity even in harsh processing environments, making these plants a trustworthy choice for industrial applications.

FAQ's of Bauxite Processing Plant:

Q: How is the capacity of the bauxite processing plant determined?

A: The plant capacity is entirely customizable to meet specific production requirements. Our team will assess your operational needs and tailor the plant design accordingly, ensuring optimal throughput and efficiency.Q: What is the installation process for the bauxite processing plant?

A: We provide on-site installation as part of our turnkey solution. Skilled technicians will oversee the assembly, commissioning, and initial testing to guarantee a smooth and timely setup at your facility.Q: When can after-sales service be expected?

A: After-sales support is available as soon as the installation is complete. Our service includes operational guidance, maintenance, and troubleshooting to ensure uninterrupted plant performance.Q: Where can the bauxite processing plant be used?

A: These plants are suitable for a range of industrial applications, including refineries, mining sites, and chemical processing facilities. They are designed to fit seamlessly into new or existing industrial infrastructures.Q: What is the primary process involved in bauxite processing?

A: The plant automates the crushing, screening, refining, and chemical processing stages of bauxite, ensuring efficient separation and preparation of the material for further industrial use.Q: How does the plant ensure low power consumption and durability?

A: Our design integrates energy-efficient electric drives and automation, keeping energy costs low. The plant's structure employs corrosion-resistant materials and a protective paint coating for enhanced durability in demanding environments.Q: What are the main benefits of using a turnkey bauxite processing plant?

A: Choosing our turnkey solution provides streamlined installation, customized capacity, advanced automation options, and robust after-sales support, leading to increased productivity, reduced downtime, and long-term operational reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese