Biomass Handling Plant

MOQ : 1 Unit

Biomass Handling Plant Specification

- Condition

- New

- Max. Lifting Load

- 1-3 Tonne

- Max. Lifting Height

- 30 Foot (ft)

- Power Source

- Electric

- Voltage

- 440 Volt (v)

- Feature

- High efficiency

- Warranty

- Yes

- Attributes

- Strong

Biomass Handling Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10 Units, , Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Biomass Handling Plant

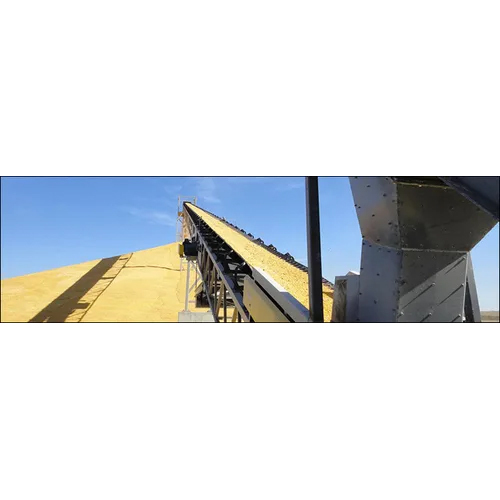

Biomass Handling Plant Rollcons Biomass Handling Plant is engineered for reliable collection, storage, and feeding of biomass materials such as wood chips, husk, pellets, and agricultural residues. Designed for minimal energy loss and maximum throughput, our systems are trusted globally with 700+ projects delivered. We deliver worldwide.

Key Features:

- Handles bulk and baled biomass

- Integrated dust suppression and fire safety

- Energy-efficient conveyors and storage systems

- Tailor-made to suit boiler/gasifier interface

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Biomass Handling System Category

Bagasse Handling System

Price 800000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 2050 Kilograms (kg)

Max. Lifting Load : 13 Tonne

Product Type : Bagasse Handling System

Type : Handling System

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese