Bagasse Handling System

Price 800000 INR/ Unit

MOQ : 1 Unit

Bagasse Handling System Specification

- Condition

- New

- Max. Lifting Load

- 1-3 Tonne

- Product Type

- Bagasse Handling System

- Power Source

- Electric

- Voltage

- 440 Volt (v)

- Feature

- High efficiency

- Warranty

- 12 Months

- Attributes

- Strong

Bagasse Handling System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units, , Per Month

- Delivery Time

- 12 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- Main Domestic Market

- All India

About Bagasse Handling System

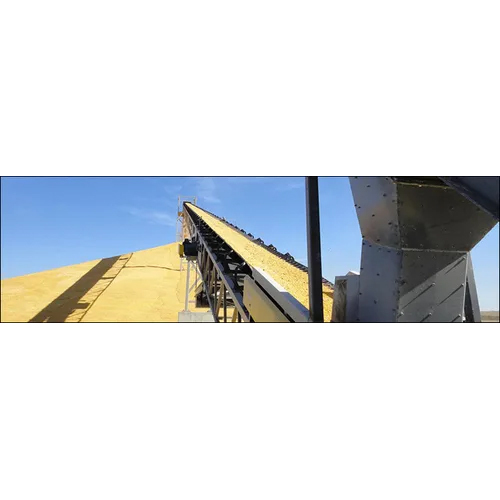

Bagasse Handling System Maximize your sugar plant's efficiency with Rollcons Bagasse Handling System built for high-volume material flow and minimal operational hassle. From feeding to conveying, our system ensures smooth, non-clogging transport of fibrous bagasse. With 700+ successful installations, we understand industry needs and deliver custom solutions globally. We deliver worldwide.

Key Features:

- Robust design to handle fibrous, moist materials

- Easy maintenance and minimal downtime

- High throughput and energy efficiency

Suitable for boiler feeding and storage

High-Efficiency Stainless Steel Build

This Bagasse Handling System is constructed from premium stainless steel, offering exceptional strength and durability for rigorous industrial applications. Its streamlined structure, measuring 1500 x 760 x 700 mm, ensures steady performance and ease of installation. Engineered for high-efficiency handling, it suits both compact and large-scale facilities across various sectors.

Powerful Capacity and Computerized Operation

With a remarkable handling capacity of 1360 tons per day and a max lifting load of up to 3 tonnes, this system delivers unparalleled throughput. Advanced computerized controls enable precise and smooth operation, reducing manual intervention and enhancing overall productivity. It operates seamlessly on standard electric supplies, making it versatile for diverse industrial environments.

FAQ's of Bagasse Handling System:

Q: How does the computerized system improve bagasse handling efficiency?

A: The computerized controls automate various handling processes, enabling precise, consistent operations while minimizing manual effort and reducing downtime, which collectively boost productivity and efficiency.Q: What materials are used in the construction of this handling system?

A: This Bagasse Handling System is fabricated from high-grade stainless steel, ensuring robust performance, corrosion resistance, and longevity under demanding industrial conditions.Q: When should maintenance be carried out on the system?

A: Regular maintenance should be conducted according to the manufacturer's guidelines, typically every few months or after high-volume usage, to ensure smooth operation and extend equipment lifespan.Q: Where is this bagasse handling system typically used?

A: It is commonly utilized in industries that process or generate bagasse, such as sugar mills and bioenergy plants, and is ideal for facilities in India seeking efficient bulk material handling solutions.Q: What is the installation process for this handling system?

A: Installation involves positioning the unit in the intended location, ensuring proper electrical connections (compatible with 220-300V or 440V), and calibrating the computerized controls, all of which are supported by manufacturer-provided setup guidelines.Q: How does the system benefit facility operations?

A: Key benefits include increased material handling efficiency, reduced manual labor, improved safety, and consistent performance due to the system's strong build and advanced controls.Q: What is the usage capacity and lifting capability of the system?

A: The system is designed to handle up to 1360 tons of bagasse per day and can lift loads ranging from 1 to 3 tonnes, catering to heavy-duty operational requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Biomass Handling System Category

Biomass Handling Plant

Price Range 200000.00 - 400000.00 INR

Minimum Order Quantity : 1 Unit

Max. Lifting Load : 13 Tonne

Power Source : Electric

Condition : New

Equipment Type : Biomass Handling Plant

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese